Logistics and manufacturing are changing fast - this is what it means for employees and employers

Logistics and manufacturing remain two of the most dynamic sectors in the Netherlands in 2026. Automation, digitalization and changing customer expectations mean that jobs are evolving rapidly. Companies are looking for employees who can do more than just execute: insight, flexibility, initiative and technical skills will become increasingly important. But which skills will really make the difference in 2026? And how do you prepare yourself or your organization for this?

Basic technical skills are becoming indispensable

Machines, software and automated systems are taking over more and more tasks. As a result, technical insight is becoming essential, even in jobs where it used to be less necessary. Think of operating modern logistics equipment, working with scanning and tracking systems or interpreting process data. Candidates who want to grow in the industry would do well to further develop their technical skills. On our page working in the Netherlands read more about what it takes to get started in these industries.

Digital skills are rising in value

Processes in warehouses and production lines are increasingly controlled by software. From inventory management systems to scheduling software - employees need to be able to interact with digital tools. That doesn't mean you need to be a programmer, but it does mean you need to be able to switch gears within modern systems. Companies that invest in this see employees working faster and more accurately.

Communication and collaboration remain crucial

Where automation supports processes, human contact remains central. Teams must work together smoothly, especially during busy periods. Good communication - clear, concise and structured - is a skill that will be increasingly important in 2026. For employees working together internationally, clear communication is especially valuable. See also our page live in the Netherlands for employees who are new arrivals here.

Flexibility and ability to learn determine your future

Logistics and manufacturing never stand still. Companies change systems, methods and processes. Employees who can adapt quickly and are eager to learn new things therefore have a great advantage. Employers in 2026 see especially great potential in people with an eagerness to learn and a willingness to take responsibility.

Why soft skills are becoming increasingly important

Soft skills such as problem solving, stress resistance and prioritization are becoming at least as important as technical skills. They determine how well a person functions within modern teams. Especially in roles with a lot of variety - such as operator, assembly worker or logistics worker - soft skills make the difference in quality and growth.

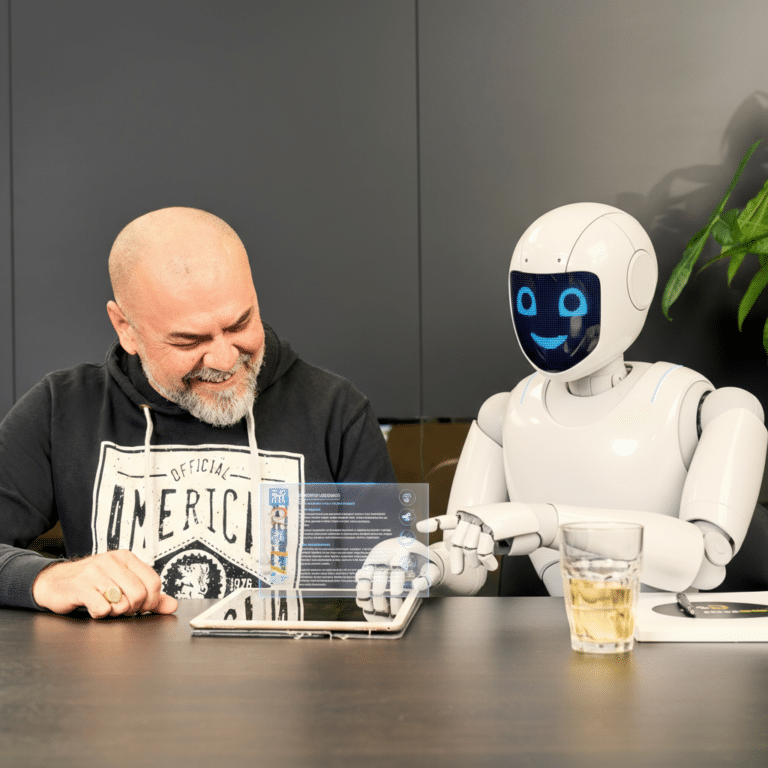

How Job Invest helps talent and employers

We see every day how fast the industry is changing and what skills are important. By looking at skills and motivation rather than just experience, we find positions for candidates where they can really grow. For employers, this means getting sustainable matches that fit the future of their business.

Ready to take the next step in logistics or manufacturing?

Whether you're an employee looking to develop or an employer looking for the right talents, understanding the skills of the future is key. At our apply-guide find tips for presenting your resume and skills strongly. Are you ready for a new position in the industry? Then check out the latest opportunities on our jobs page.